Our Equipment

Equipment Cleaning & Recovery of Sludge

Zajel Company for Oil and Technical Services is a specialized provider in the field of industrial cleaning, sludge treatment, and mechanical services for the oil and gas sector. The company has successfully executed a wide range of projects involving the removal, treatment, and safe disposal of hydrocarbon sludge, the internal and external cleaning of large storage tanks, oil transfer logistics, and the rehabilitation of contaminated oil pits.

Our work is carried out by international standards for environmental protection, safety, and operational efficiency. Zajel integrates advanced technologies such as non-entry tank cleaning systems, mobile oil-water separators, high-pressure hydro-jetting units, and sludge cutters to ensure clean, safe, and productive environments across all operational sites.

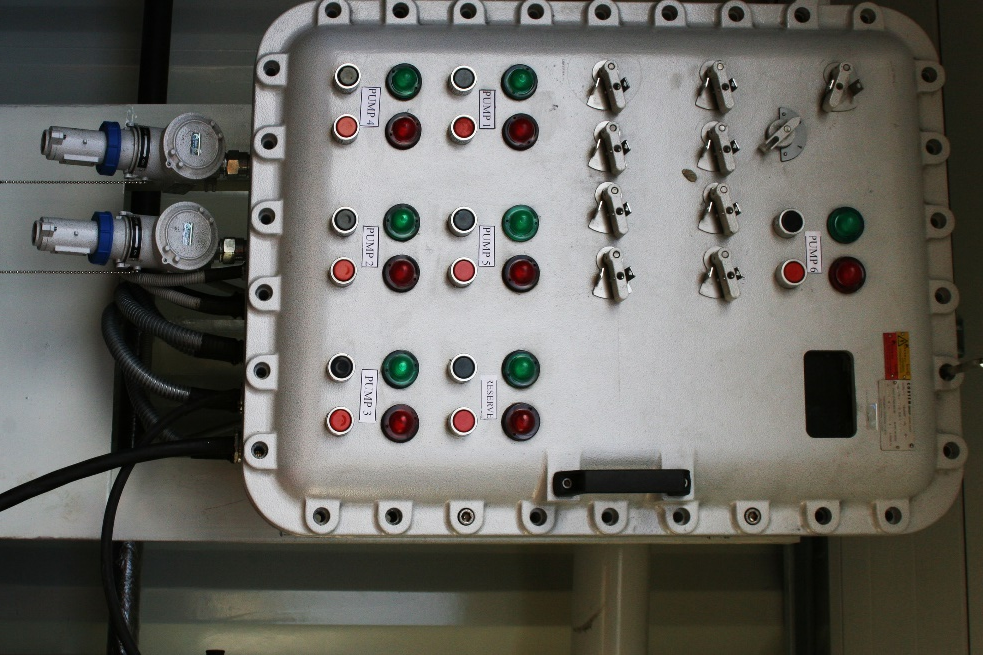

To ensure operational safety:

All equipment is explosion-proof or ATEX-rated where required. Hydraulic and pneumatic systems are prioritized over electrical components to reduce ignition risks. Grounding, bonding, and continuous gas monitoring are enforced on all active sites

Mobil Cleaning Unit MKO-1000, MKO-1003 for tanks, pits, and Chemical Tankers.

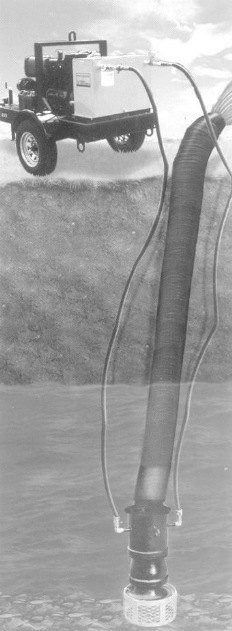

Vacuum Pumps and Hydraulic Submersible Pump System.

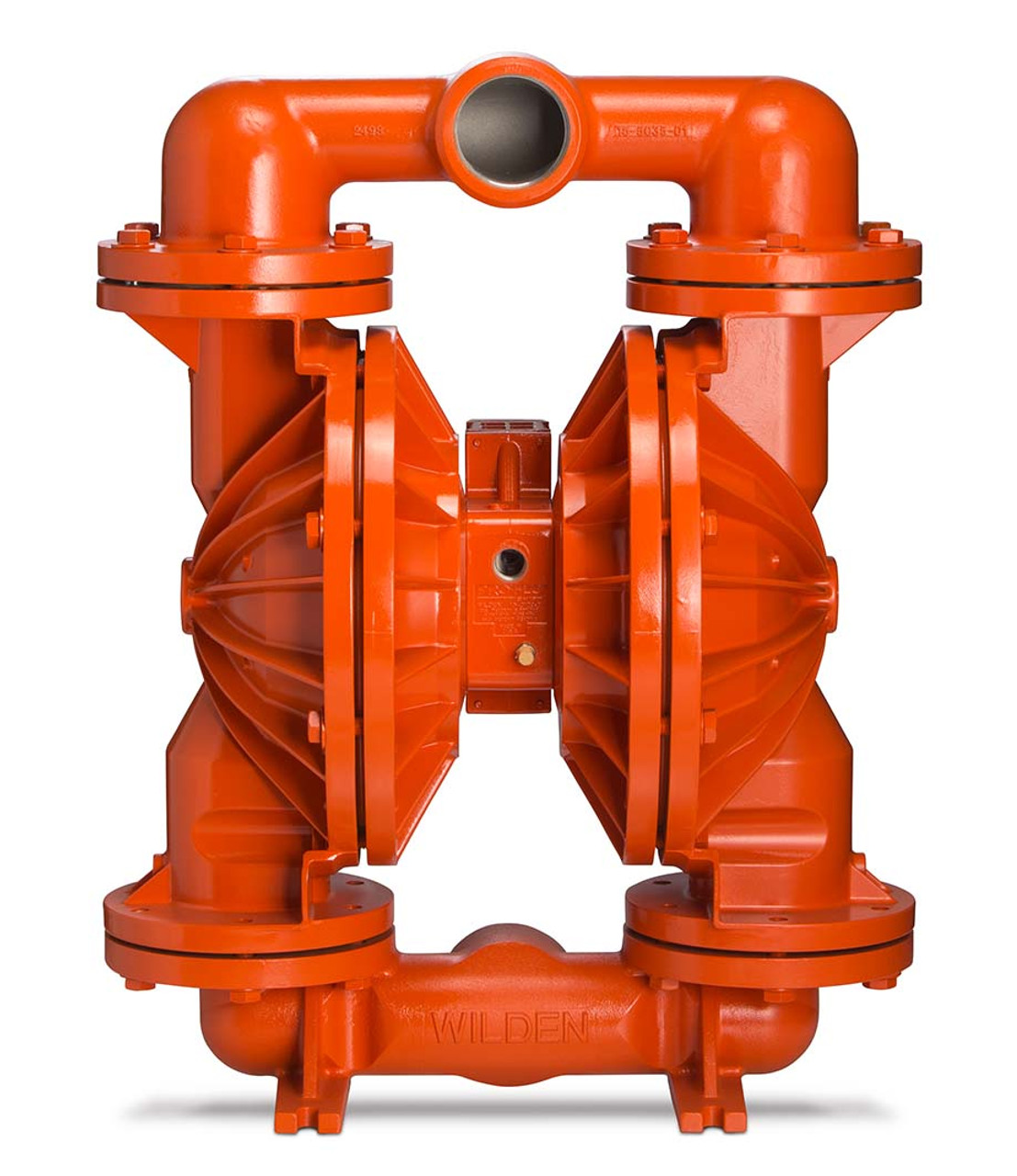

Equipment Profile: Wilden 3" Air-Operated Vacuum Transfer Pump (Draft)

Function: Mobile, high-suction transfer of oil sludge, oily water, and semi-solid sediments during tank cleaning, pit recovery, and emergency transfer operations.

Pump Type: Air-operated double-diaphragm (AODD) / vacuum-assist transfer assembly (field skid-mounted).

Connection Size: 3-inch suction and discharge (camlock or flange, depending on setup).

Pumping high-viscosity sludge and sediment-laden liquids directly from tanks, pits, or lagoons.

Operating in submerged conditions, with excellent suction capabilities even under challenging sludge depth or oil-layered water surfaces.

Minimizing downtime due to clog-resistant impellers and robust construction, ideal for continuous-duty applications

Pump High Capacity

Centrifugation Pump – Role in Sludge and Oil Treatment Operations

The Centrifugation Pump is an essential component in Zajel Company’s operations for separating, processing, and transferring oil-contaminated fluids. Used in conjunction with centrifuge units or oil-water separation systems, this pump ensures a steady and controlled feed of high-viscosity sludge or emulsified hydrocarbons into the treatment system.

Hydro-cyclone

The Hydro-cyclone is located in the MKU unit inlet; its role is to separate the fine solid particles from the liquid before transfer.

Lifting and Handling Operations

Zajel Company places strong emphasis on safe and efficient lifting and material handling operations, particularly in confined and hazardous oilfield environments. These operations are critical during tank dismantling, sludge removal, equipment mobilization, and structural modifications.

Our lifting activities are executed using:

- Certified mobile cranes, hydraulic lifting frames, and hoisting gear.

- Rigging systems and spreader beams for balanced and controlled movement.

- Skilled operators and riggers trained under international safety standards (such as LOLER and OSHA).

Each lifting operation is preceded by a method statement, risk assessment, and load path analysis to ensure safety, efficiency, and minimal disruption to surrounding operations.

Telescopic Forklift (JCB)

The Telescopic Forklift (JCB) plays a vital role in on-site logistics and material handling throughout Zajel Company’s field operations. This versatile equipment is used for lifting, transporting, and positioning heavy loads in areas where cranes or traditional forklifts may not be practical.

Telescopic Mobile Crane

The Telescopic Mobile Crane is one of the core lifting assets deployed by Zajel Company in oil tank cleaning, demolition, and equipment installation projects. Its extendable boom design offers both height flexibility and reach, making it ideal for confined sites and variable load-handling conditions.

Hydraulic Steering Modular Transport Truck

Zajel Company utilizes Hydraulic Steering Modular Transport Trucks to safely and efficiently transport heavy and oversized equipment across operational sites. This trailer system is engineered for the precision movement of high-tonnage loads.

CAT 350E (Scissors)

The CAT 350E Scissor Lift is a vital access platform used by Zajel Company during cold cutting operations, especially in the dismantling of large oil tanks and steel structures. Its stable, hydraulically elevated platform provides safe vertical access for technicians operating cold cutting machines (such as Caesar saws and hydraulic shears).

Mobile Air Compressor – Pneumatic Power Source (22 & 5.2 M²)

The Mobile Air Compressor is a key support unit deployed by Zajel Company across various oil tank maintenance and demolition projects. It serves as a primary pneumatic power source for operating air-driven tools such as cold cutting machines, pneumatic chisels, impact wrenches, and sludge agitators.

Automatic MIG/MAG Gas-Shielded Arc Welding Machine

Zajel Company utilizes Automatic MIG/MAG Gas-Shielded Arc Welding Machines for high-quality welding during the repair, modification, and fabrication of steel structures, including oil tanks, pipe fittings, and support assemblies, consistent welds with increased efficiency compared to manual processes

Ambulances – On-Site Emergency Medical Response

Zajel Company maintains dedicated ambulances on-site as part of its commitment to health and safety compliance in hazardous oilfield environments. These vehicles are fully equipped to provide immediate medical support in case of injury, chemical exposure, or other emergencies.

Personnel Bus – Workforce Transportation and Site Access.

Zajel Company provides dedicated personnel buses to ensure the safe and timely transportation of its workforce to and from project sites. These buses are a key element of the company’s logistical operations, enabling structured crew mobilization and minimizing delays in daily site activity.

Generator – Primary and Backup Power Supply

Zajel Company deploys industrial-grade generators to supply continuous and backup electrical power for remote tank cleaning, demolition, and oilfield support operations. These generators are essential for maintaining operational continuity in areas with unreliable grid access or during critical phases where uninterrupted power is vital.

Mobile Diesel Truck – On-Site Fuel Supply and Logistics Support

Zajel Company operates mobile diesel trucks to provide a reliable fuel supply for equipment and machinery operating in remote and continuous-use environments. These trucks play a crucial role in supporting the operational demands of generators, pumps, heavy-lifting equipment, and transport vehicles across tank maintenance and demolition projects.

Dump Trucks – Material Transport and Earthmoving Support

Zajel Company utilizes heavy-duty dump trucks for the efficient transportation of materials such as excavated soil, sludge, construction debris, gravel, and engineered fill across tank rehabilitation, demolition, and civil preparation sites. These vehicles are essential for maintaining clean and organized work zones, particularly during large-scale tank cleaning, backfilling, and foundation reconstruction.

Compactor Machines.

Zajel Company deploys soil compactor rollers as part of its earthwork and tank foundation preparation operations. These machines play a critical role in achieving the required soil density and compaction standards during internal and external backfilling, especially for crude oil tank bases and surrounding containment berms

Boom Truck

Cut Cylinders – Controlled Cutting for Steel Plate and Shell Sections.

Zajel Company employs cutting cylinders as part of its specialized toolkit for tank demolition and controlled dismantling operations. These devices are typically hydraulic or pneumatic actuated cutting tools designed to slice through thick-walled steel structures, such as tank shells, floors, and roof sections, with high precision and safety.

Saviour Stainless Steel Airline Trolley – Breathing Support in Confined and Hazardous Spaces

Tractor

West Oasis Company.

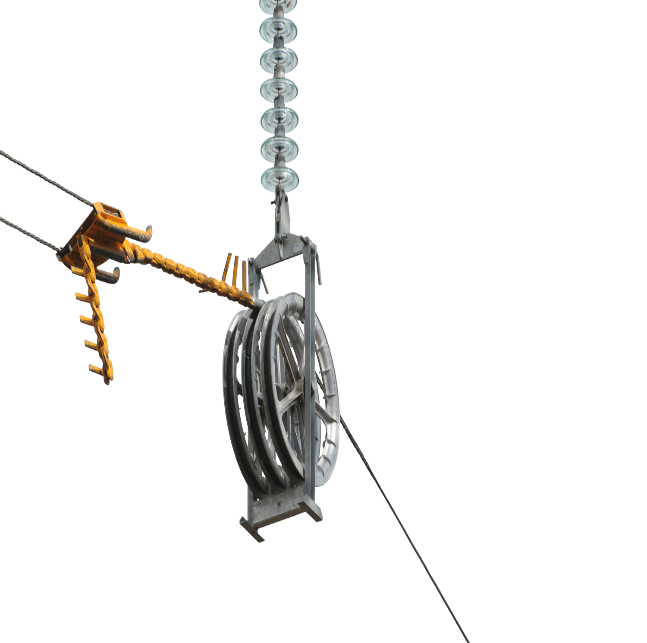

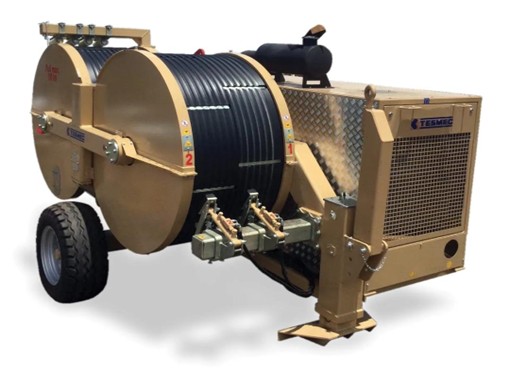

Stringing Machine and Accessories

West Oasis Company operates specialized stringing machines for the installation of insulators and conductors on overhead transmission lines. These machines are crucial for maintaining tension control, ensuring conductor integrity, and ensuring the safe installation of electrical components in high-voltage environments.

Equipment List

| ITEM | EQUIPMENT DESCRIPTION | QUANTITY REQUIRED |

|---|---|---|

| 1 | Crane 50-Ton (RIGO) | 2 |

| 2 | Crane 50-Ton (GROVE) | 1 |

| 3 | Crane 65-Ton (ERKINE) | 2 |

| 4 | Crane 65-Ton (TADANO) | 1 |

| 5 | MAN, Prime Mover | 4 |

| 6 | IVECO Prime Mover | 1 |

| 7 | Fork Lifts (3-7 Ton) | 4 |

| 8 | Dump Truck | 1 |

| 9 | Tractor | 1 |

| 10 | Small Sedan Cars | 10 |

| 11 | 4 X 4 Vehicle (pick up) | 10 |

| 12 | BUS 9 Passenger | 2 |

| 13 | BUS 24 Passenger | 1 |

| 14 | Roller 5 Ton | 1 |

| 15 | 32 Axel Caprie (Hydraulic Trailers) | 32 |

| 16 | Generators 75 KV | 3 |

| 17 | PLAZMA Cutting Machine | 1 |

| 18 | Cable Pulling Machine | 2 |

| 19 | Living Containers | 10 |

| 20 | Containers | 20 |

| 21 | MKO Tank Cleaning | 2 |

| 22 | Centrifugal Pumps | 1 |

| 23 | TGU Heating System | 1 |

| 24 | ATEX Pumps | 10 |

| 25 | Tank Jak System 12 To 90 + Power House | 1 |

| 26 | Oil Skimmer | 1 |

| 27 | Hydro Test Fuel Pump 1000 m3/h | 1 |

| 28 | Compressors (12 Bar) | 2 |

| 29 | Pioneer Pump for (OIL & GAS) | 5 |

| 30 | Diesel Tank (7000 L To 10000 L) | 3 |

| 31 | Flat Bed Trailers | 3 |

| 32 | Truck Trailer | 1 |

| 33 | Welding Machine | 20 |

| 34 | Welding Tractor Automatic | 3 |

| 35 | Miller Welding Machines | 20 |

| 36 | Total Station | 1 |

| 37 | Concert Mixer | 2 |

| 38 | Scaffolding 1700 m2 | 1 |

| 39 | Water pump (Electric-for Water) | 1 |

| 40 | Diesel Tank | 4 |

| 41 | Jack Hammers | 4 |

| 42 | Hydraulic Cutter | 5 |

| 43 | Stringing Machines (TESMAC) | 3 |

| 44 | Abrasive Machine | 3 |

| 45 | Compactors | 3 |

| 46 | CBC 100 PRIMARY INJECTION (Testing Device) | 1 |

| 47 | CMC 356 SECONDARY INJECTION (Testing Device) | 1 |

| 48 | MAGGER (Testing Device) | 1 |

| 49 | EARTHING TESTING | 2 |

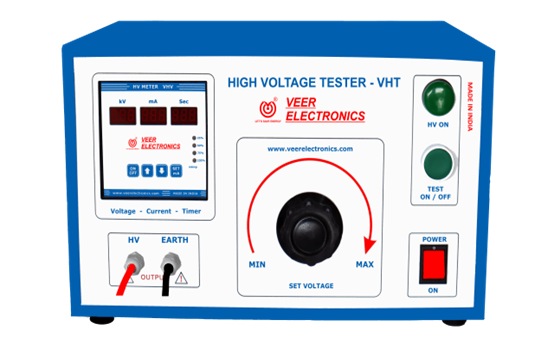

| 50 | HIGH VOLTAGE TEST | 1 |

| 51 | TIME CLOSE (Testing Device) | 1 |

| 52 | TAN DELTA TDI DEVICE | 1 |

To ensure operational safety:

- All Equipment is explosion-proof or ATEX-rated where required.

- Hydraulic and pneumatic systems are prioritized over electrical components to reduce ignition risks.

- Grounding, bonding, and continuous gas monitoring are enforced on all active sites.

Equipment & Testing Devices Overview

Stringing Machine (TESMAC)

West Oasis Company operates specialized stringing machines for the installation of insulators and conductors on overhead transmission lines. These machines are crucial for maintaining tension control, ensuring conductor integrity, and ensuring the safe installation of electrical components in high-voltage environments.

CPC 100 Device

The CPC 100 is a universal primary injection testing device developed by OMICRON, designed for commissioning and maintaining electrical substation assets. It’s like the Swiss Army knife of electrical testing—compact, powerful, and versatile.

- Replaces multiple individual testing devices, saving time and cost.

- Performs primary injection testing, which verifies the entire protection chain in systems like circuit breakers.

- Tests a wide range of equipment: transformers, CTs, VTs, circuit breakers, grounding systems, cables, and rotating machines.

- Outputs up to 800 A or 2 kV, expandable to 2000 A or 15 kV with boosters.

- Operates across a frequency range of 15 Hz to 400 Hz, or 400 A DC.

- Weighs just 29 kg, making it ideal for field use.

- Offers automated testing procedures and report generation via Primary Test Manager™ software.

- Meets IEEE and IEC safety standards.

- Includes emergency shut-off and protective earth connection checks.

This device is a go-to for engineers working in substations who need reliable, efficient, and accurate testing.

CMC 356 SECONDARY INJECTION (Testing Device)

The CMC 356 by OMICRON is a universal relay test set and commissioning tool used primarily for secondary injection testing in electrical systems. It’s designed to simulate fault conditions and verify the correct operation of protection relays without needing to energize the entire system.

- Simulates electrical faults (voltage/current anomalies) to test protection relays.

- Verifies relay settings and response times.

- Performs wiring and plausibility checks on current transformers.

- Supports IEC 61850 testing for digital substations.

- Six current sources (up to 64 A / 860 VA per channel in 3-phase mode).

- Four voltage sources (up to 300 V per channel).

- High accuracy and dynamic range for testing electromechanical, static, and numerical relays.

- 10-channel analog measurement and transient recording (optional).

- Software integration with Test Universe, Relay Sim Test, and CM Control P for automated and manual testing.

MAGGER (Testing Device)

This is a specialized electrical testing device used to measure insulation resistance in electrical components and systems. It’s a crucial tool for ensuring safety and reliability in installations like motors, transformers, cables, and switchgear.

- Insulation resistance between conductors and ground.

- Leakage current resulting from moisture, dirt, or damage.

- The integrity of windings in motors and electrical systems in general.

EARTHING TESTING

An Earthing Test is a safety check used to ensure that electrical systems are properly connected to the ground. This connection allows fault currents—like those from lightning or equipment failure—to safely dissipate into the earth, protecting people and equipment from electric shock and fire hazards.

It's Important:

- Prevents electric shocks

- Reduces risk of equipment damage or fire

- Ensures compliance with safety standards (IEC, IEEE, NEC)

HIGH VOLTAGE TEST

A High Voltage Test is a critical procedure used to verify the insulation integrity and electrical safety of equipment designed to operate under high voltage conditions. It ensures that components like transformers, cables, switchgear, and insulators can withstand voltage stresses during normal operation and fault conditions.

Purpose of the Test:

- Evaluate dielectric strength of insulation materials.

- Detect manufacturing defects or contamination.

- Verify compliance with standards (IEC, IEEE, ANSI).

- Estimate equipment lifespan under electrical stress.

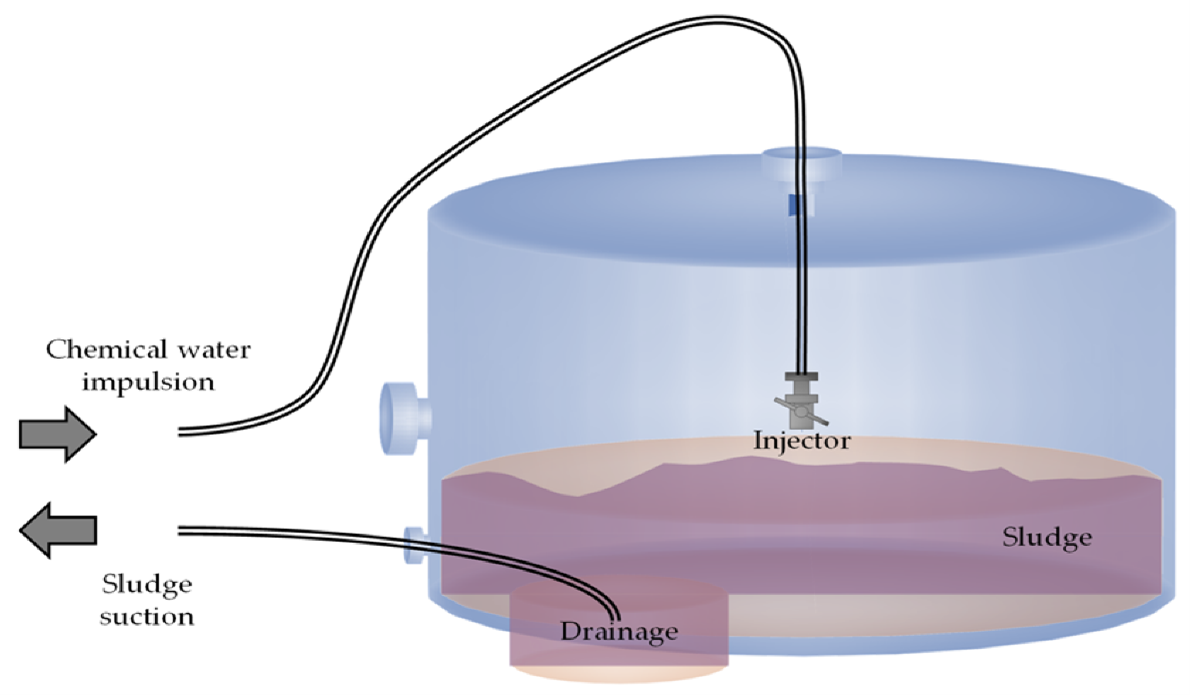

MOBIL CLEANING UNIT MKO-1000, MKO-1003

This equipment is designed for cleaning oil tanks, oil waste pits, and chemical storage tanks. It provides high suction for oil sludge, oil-contaminated water, and semi-solid sludge during tank cleaning.

Hydro-cyclone

The Hydro-cyclone is located in the MKU unit inlet, used to separate particles in a liquid suspension based on their size and density—without any moving parts. It’s widely used in industries like oil & gas, mining, food processing, and wastewater treatment.

Centrifugation Pump

Used in conjunction with centrifuge units or oil-water separation systems, this pump ensures a steady and controlled feed of high-viscosity sludge or emulsified hydrocarbons into the treatment system. It is a mechanical device that moves fluids by converting rotational kinetic energy—usually from an electric motor—into hydraulic energy. It’s one of the most widely used types of pumps in industries like oil & gas, water treatment, and chemical processing.

Pioneer Pump for Oil & Gas

It is the high-performance centrifugal pump tailored for the extreme demands of oil and gas operations. These pumps are built to handle tough environments and critical tasks.

Main Functions of a Pump:

- Crude Oil Transport: Transporting crude oil from storage tanks to cargo ships.

- Drilling Mud Transport: Efficiently transporting abrasive drilling fluids.

- Water Transport: Supporting operations such as hydraulic fracturing and dewatering from the site.

- Fracturing Feed Systems: Delivering water and chemicals to fracturing sites.

- Pipeline Testing and Oil Tank Cleaning: Ensuring system safety and cleanliness.

- Firefighting and Emergency Response: Providing high-pressure water delivery to remote locations.

Automatic MIG/MAG Gas-Shielded Arc Welding Machine

This machine is a semi- or fully-automated welding system that performs Gas Metal Arc Welding (GMAW) using either MIG (Metal Inert Gas) or MAG (Metal Active Gas) processes. It’s widely used in industries like huge oil tanks, pipeline construction, and heavy fabrication for its speed, precision, and adaptability.

Lifting and Handling Operations

WEST OASIS Company places strong emphasis on safe and efficient lifting and material handling operations, particularly in confined and hazardous oilfield environments. These operations are critical during tank dismantling, sludge removal, equipment mobilization, and structural modifications.

Our lifting activities are executed using:

- Certified mobile cranes, hydraulic lifting frames, and hoisting gear.

- Rigging systems and spreader beams for balanced and controlled movement.

- Skilled operators and riggers trained under international safety standards (such as LOLER and OSHA).

Each lifting operation is preceded by a method statement, risk assessment, and load path analysis to ensure safety, efficiency, and minimal disruption to surrounding operations.

Telescopic Mobile Crane

The Telescopic Mobile Crane is one of the core lifting assets deployed by WEST OASIS Company in oil tank cleaning, demolition, and equipment installation projects. Its extendable boom design offers both height flexibility and reach, making it ideal for confined sites and variable load-handling conditions.

CAT 350E Scissor Lift

The CAT 350E Scissor Lift is a vital access platform used by WEST OASIS Company during cold cutting operations, especially in the dismantling of large oil tanks and steel structures. Its stable, hydraulically elevated platform provides safe vertical access for technicians operating cold cutting machines (such as Caesar saws and hydraulic shears).

Telescopic Forklift (JCB)

The Telescopic Forklift (JCB) plays a vital role in on-site logistics and material handling throughout WEST OASIS Company’s field operations. This versatile equipment is used for lifting, transporting, and positioning heavy loads in areas where cranes or traditional forklifts may not be practical.

Hydraulic Steering Modular Transport Truck

WEST OASIS Company utilizes Hydraulic Steering Modular Transport Trucks to safely and efficiently transport heavy and oversized equipment across operational sites. This trailer system is engineered for the precision movement of high-tonnage loads.

Air Compressor

The Air Compressor is a key support unit deployed by WEST OASIA Company across various oil tank maintenance projects. It serves as a primary pneumatic power source for operating air-driven tools such as cold cutting machines, pneumatic chisels, impact wrenches, and sludge agitators.